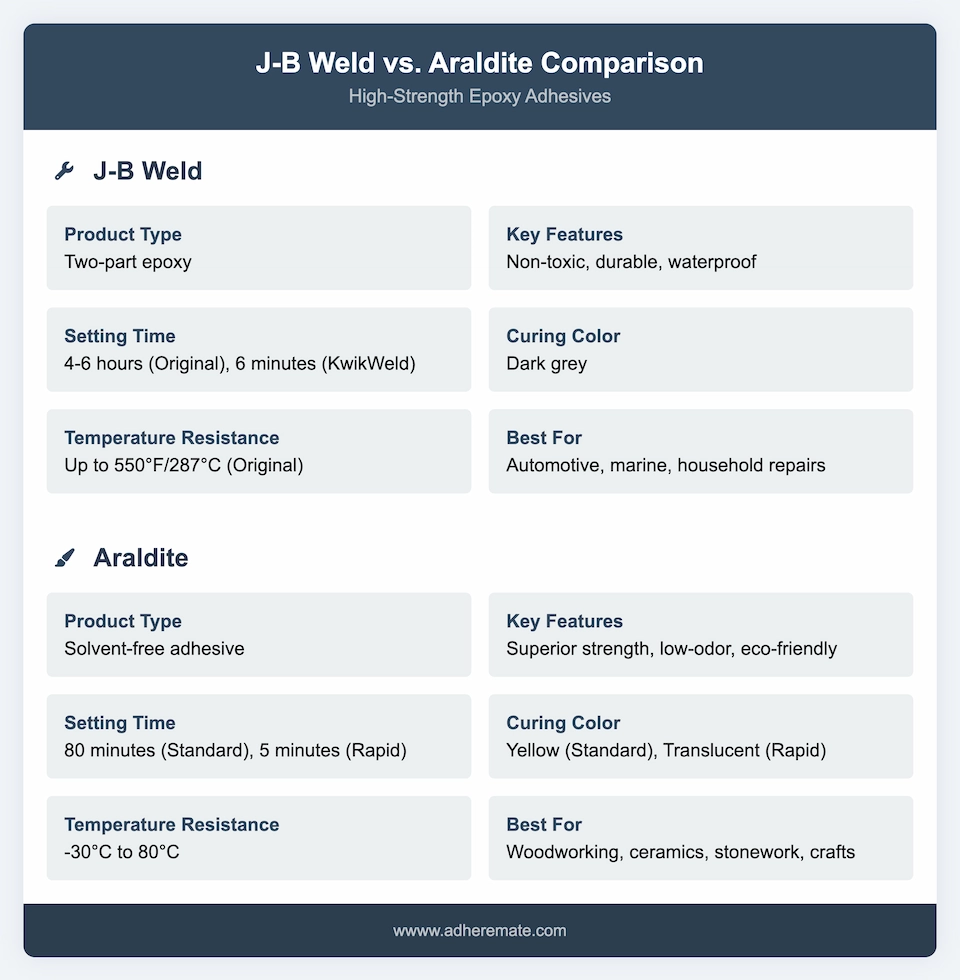

J-B Weld products are mainly two-part epoxy and provide a robust and non-toxic bond. J-B Weld Original Cold-Weld is a standard epoxy with a fast-setting version, J-B Weld KwikWeld.

Araldite adhesives are solvent-free, superior-strength adhesives. The standard one is slow-cure adhesive for complicated projects. It has a fast-setting version, Araldite Rapid translucent adhesive.

J-B Weld is compatible with automotive, household, marine, and crafts projects, and Araldite is for woodworking repairs, ceramic repairs, stonework, crafts, and more.

Read More: E6000 vs. J-B Weld

Article Highlights

- J-B Weld products are versatile, non-toxic, and durable.

- Araldite products are solvent-free, low-odor, and professional with ultra-strong hold.

- J-B Weld and Araldite include a fast-setting product that delivers quicker, stronger, and better adhesion than their original ones.

- Once cured, J-B Weld adhesives are waterproof, chemical, petroleum, fuel, and acid resistant.

- Araldite adhesives are water, oil, chemical, and impact-resistant.

JB Weld vs. Araldite

J-B Weld products like J-B Weld Original Cold-Weld and KwikWeld provide strong, lasting repairs to various surfaces. They create perfect bonds on DIY, automotive, marine, household, and crafts repairs.

J-B Weld KwikWeld is a fast-setting version of the original that provides solid and long-lasting repairs to metal and other surfaces.

Conversely, Araldite adhesives are easy to use, have superior strength, and are environmentally friendly.

Araldite Standard is an easy-to-use syringe with heavy-duty, solvent-free features. Araldite Rapid is the strong and quicker version of Araldite Standard adhesive. It is suitable for quick jobs.

Product Type

J-B Weld products come in two-part tubes. To use them, the parts need to be mixed equally.

Araldite Standard comes in a resealable syringe with a spatula for easy mixing of resin and hardener. But Araldite Rapid comes in two-part tubes, Part A and Part B.

Strength

J-B Weld is famous for its durability and high-strength formula.

This two-part epoxy can provide solid and long-lasting repairs on multiple surfaces. It is designed as an alternative to torch welding.

J-B Weld products such as J-B Weld SteelStik and TankWeld are excellent choices for heavy-duty repairs. These adhesives are designed for high-strength applications, like automotive repairs and marine maintenance.

Araldite adhesives have superior strength and a solvent-free, low-odor formula, making them ideal for durable bonding and heavy-duty hold. They are perfect for jobs that need an extra-strong hold.

Araldite Rapid adhesive is a fast-setting, long-lasting, water-resistant adhesive. It is produced to build, bond, and protect.

Read More: Devcon vs. J-B Weld

Setting And Curing Time

The J-B Weld Original one sets in 4-6 hours and cures in 15-24 hours.

But the J-B Weld KwikWeld is a faster version that sets in only 6 minutes and cures within 4-6 hours.

Once cured, it is durable and can be sanded, tapped, drilled, painted, filed, shaped, and molded.

Conversely, the Araldite Standard is a slow-cure adhesive suitable for complicated jobs that may require adjustments.

It includes a long working time, has a repositionable time of 80 minutes, and obtains full strength in 14 hours.

However, the Araldite Rapid is a fast-setting version of the standard one.

Its setting time is 5 minutes, its handling time is 20 minutes, and its curing time is 3 hours.

Araldite adhesives can be sanded, drilled, and painted.

Cure Color

J-B Weld products are cured in dark grey. Araldite products have different cure colors. Araldite Standard cures in yellow color.

However, the Araldite Rapid adhesive epoxy becomes translucent once cured, which makes it versatile for multiple repairs.

Compatible Materials

J-B Weld adhesives are suitable to work on various surfaces. The compatible materials are metal, wood, ceramic, tile, fiberglass, concrete, stone, rigid plastics, PVC,

Araldite adhesives are suitable for almost all materials. They have the highest durability on metal, wood, glass, ceramic, masonry, dry concrete, leather, chipboard, cardboard, rubber, fabric, and most plastics except polypropylene, polyethylene, and PTEE.

Applications

J-B Weld products can handle many tasks, including household repairs, marine, automotive, crafts, plumbing, DIY, repairs of outdoor equipment, agricultural equipment, toys, boats, motorcycles, personal watercraft, and more.

For example, products like J-B Weld ExtremeHeat and QuikSteel are specifically designed to withstand extreme temperatures, making them ideal for exhaust systems and engine repairs.

Araldite is suitable for ceramic repairs, woodworking, repairs, fences, stonework, outdoors, toys, and more.

The Aradite Rapid can repair automotive, ceramic goods, photo frames, plastic, outdoor, snowboard, shoe soles, and many other items. It can also effectively fill in cracks or scratches.

Araldite adhesives are easy to use, versatile, multipurpose, and suitable for indoor and outdoor projects.

They allow a stronger, cleaner, hassle-free application when compared to alternate solutions.

Also, they can be worked on with paint and sanding after setting and provides a seamless, fully workable, and professional finish.

Method of Using

J-B Weld products come in two-part tubes. First, you must mix equal amounts of both parts, mix them well, apply them to a clean and dry surface, and let them dry to form a permanent bond with a tensile strength of 5020 PSI after curing.

If you use Araldite Standard syringe adhesive, open the resealable cap first, depress the plunger, and dispense both parts equally.

The product includes a spatula for easy mixing without mess. If needed, roughen with sandpaper and degrease with a suitable solvent.

Apply the mixture and remove excess. The nozzle provides a precise and even application.

Apply pressure to the joints until appropriately set. Use tape or clamps for around 8 hours and allow 14 hours to reach full strength before sanding rough handling, or painting.

Another Araldite product is the Rapid one, which comes in two-part tubes. You need to dispense equal amounts onto a clean dispensing surface to use it.

Replace the cap, and mix the two parts thoroughly for at least 30 seconds until adequately mixed.

The mixture remains usable within 5 minutes, so apply it within that time. Apply to both surfaces and assemble carefully.

Once it’s partially set, you can remove excess adhesive with a sharp blade.

Temperature

J-B Weld products like the Original Cold-Weld one can withstand 550°F/287°C, whereas J-B Weld KwikWeld can withstand 230°F/110°C. This makes them ideal for automotive and marine applications, as seen in the comparison between J-B Weld Original Cold Weld and MarineWeld.

On the other hand, Araldite products have a temperature resistance between -30°C to 80°C.

Resistance

Once cured, J-B Weld products are waterproof, petroleum, chemical, acid, and fuel resistant. They are also strong, paintable, and sandable.

Araldite adhesives are oil, water, chemical, and impact-resistant.

They are also high-temperature resistant, low-odor, solvent-free, and professional strength for all materials.

Further, it can withstand rough handling. It is environmentally friendly and has eco-friendly packaging for easy recycling.

Editor’s Note

J-B Weld adhesives are multipurpose, two-part epoxy systems for household, automotive, and marine repairs.

Araldite adhesives are suitable for complicated repairs, and can be used on almost all materials.

The syringe one is a slow-cure adhesive that is best for precise application and complicated repairs.

The Araldite Rapid has a fast-setting formula suitable for instant repairs.

Both brands have fast-setting versions that are convenient for users.

However, Araldite’s solvent-free and eco-friendly packaging and superior strength make it ideal for professional use, whereas J-B Weld’s versatility shines in heavy-duty applications.