Not all J-B Welds are for watercraft. However, the original ones from this line are good for many other crafts, such as automotive and plumbing.

The Original Cold-Weld is a waterproof, steel-reinforced adhesive. The MarineWeld is specially formulated for marine repairs.

Both are high-quality adhesives. They are also waterproof, chemical, and acid-resistant. To learn more about them, read the article and detailed comparison below.

Read More: JB Weld ClearWeld vs. Original Cold-Weld

Article Highlight

- The J-B Weld Original Cold-Weld is a two-part steel-reinforced epoxy system designed as an alternative to traditional torch welding.

- The J-B Weld MarineWeld is a specially formulated two-part marine epoxy that provides solid and long-lasting repairs.

- Cold-Weld has a liquid, gel-like formula, whereas MarineWeld has a thick paste formula.

- Both are waterproof, cure dark gray, and are compatible with household, automotive, and marine applications.

JB Weld Original ColdWeld vs. MarineWeld

J-B Weld Original Cold-Weld is a steel-reinforced epoxy with great strength and performance to work on household and automotive repairs.

Another product is the J-B Weld MarineWeld. It is a specially formulated two-part adhesive that is for marine and watercraft.

They are similar in some points but have different purposes for repairs. Check out the detailed comparison to learn more.

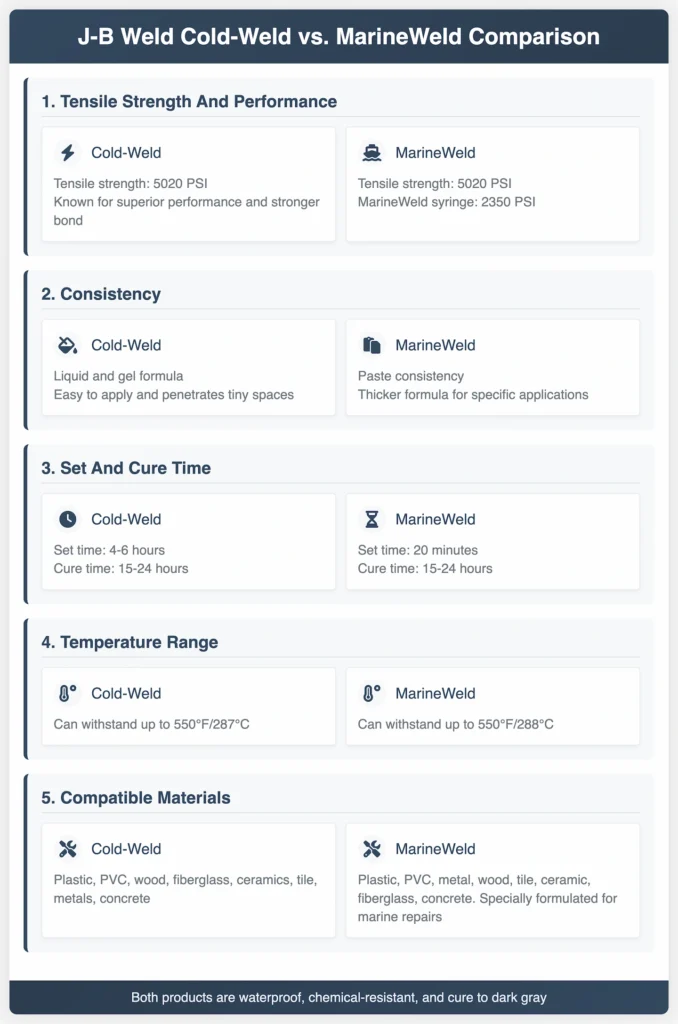

1. Tensile Strength And Performance

J-B Weld Original Cold-Weld: it provides strong and long-lasting results. The J-B Weld Cold-Weld has a tensile strength of 5020 PSI. To deliver superior performance, quality, and a stronger bond, this product is well-known.

J-B Weld MarineWeld: The MarineWeld is a two-part epoxy that needs to be mixed in a 1:1 ratio. It can also provide superior performance and equality.

This product’s tensile strength is 5020 PSI, similar to cold-weld.

However, if we look into another product in the MarineWeld category, the MarineWeld syringe is less strong with 2350 PSI.

2. Consistency

J-B Weld Original Cold-Weld: Cold-Weld has a liquid and gel formula, making it more accessible and convenient to apply.

You need to mix the two-part 1:1 ratio to form a permanent bond.

J-B Weld MarineWeld: MarineWeld comes with a paste consistency.

So, there’s a big difference in terms of its formulation.

Because of their consistency, cold welds are more likely to penetrate the tiniest places and spread easily.

3. Set And Cure Time

J-B Weld Original Cold-Weld: The Cold-Weld takes 4-6 hours to set and around 15-24 hours to cure properly.

Once cured, it can be sanded, drilled, molded, tapped, and shaped. All you need to do is prepare, mix, apply, and dry.

J-B Weld MarineWeld: MarineWeld sets in 20 minutes at room temperature and fully sets in 4-6 hours.

Also, it takes 15-24 hours to cure, after which it can be sanded, shaped, drilled, filed, tapped, and reached full strength below or above the water’s surface.

There is no such difference between the two products. However, the MarinWeld syringe version is much quicker than Cold-Weld. It takes only 5 minutes to set and an hour to cure.

4. Temperature

J-B Weld Original Cold-Weld: The Original Cold-Weld can withstand temperatures up to Can withstand 550°F/287°C.

J-B Weld MarineWeld: MarineWeld can withstand temperatures up to 550°F/288°C.

So, comparing these two epoxies according to temperature is almost the same. Both can be used effectively within this limit.

Read More: J-B WaterWeld vs. MarineWeld vs. Original Cold-Weld

5. Color

J-B Weld Original Cold-Weld: When it comes to the basics, like the cure color, the Cold-Weld becomes dark gray.

J-B Weld MarineWeld: The other product is MarineWeld, and the cure color is the same: dark gray.

6. Compatible Materials

J-B Weld Original Cold-Weld: J-B Weld Cold-Weld can be used on multiple materials. It is compatible with plastic, PVC, wood, fiberglass, ceramics, tile, metals, and concrete.

J-B Weld MarineWeld: MarineWeld is compatible with plastic, PVC, metal, wood, tile, ceramic, fiberglass, and concrete.

However, It is specially formulated for use in marine repairs.

7. Applications

J-B Weld Original Cold-Weld: This original Cold-Weld can be used on household, automotive, plumbing, crafts, agricultural equipment, toys, boats, personal watercraft, motorcycles, deck and hull accessories, inboard and outboard engines, and marine purposes.

J-B Weld MarineWeld: MarineWeld can be used to repair marine, automotive, household, plumbing, crafts, outdoor equipment, agricultural equipment, toys, motorcycles, boats, deck and hull accessories, inboard and outboard engines, watercraft, and more.

Apply the epoxy with the proper tools to make the application more accessible and more even.

For projects involving plastic surfaces, you might want to compare J-B WaterWeld against PlasticWeld to find the best option for your needs.

8. Resistance

J-B Weld Original Cold-Weld: When discussing resistance, J-B Weld Original Cold-Weld has a resistance to water, chemicals, petroleum, and acid once fully cured.

J-B Weld MarineWeld: When properly cured, MarineWeld is waterproof, chemical, petroleum, and acid-resistant.

Editor’s Opinion

Although they share some similar qualities, MarineWeld is more likely to be able to work in wet areas. Cold-Weld claims to work on household and automotive repairs, and the MarineWeld is known for marine repairs with waterproof quality.

Based on our research, both work almost the same. You can use either of them. But for working in wet areas or especially for marine applications, J-B Weld MarineWeld is the one.

For tips on ensuring a strong bond in high-moisture environments, this guide on marine epoxy application techniques offers practical advice.