J-B Weld produces high-quality products, and J-B Weld KwikWeld and Original Cold-Weld are no different.

KwikWeld is a quick-setting epoxy that can have lasting effects on all your repairing tasks. The Cold-Weld takes time to set but delivers a permanent outcome to the surface.

Both have good features that you will surely want to know. Dive into the details to learn more.

Read More: J-B Weld ClearWeld vs. Original Cold-Weld

Article Highlights

- KwikWeld is for quick repair; it is the fast-setting version of The Original J-B Weld two-part epoxy Cold-Weld system.

- The Original steel reinforced Cold-Weld is a multipurpose epoxy that provides a lasting outcome.

- KwikWeld and Cold-Weld can be sanded, drilled, and tapped after adequately curing.

- Cold-Weld is noticeably a better strength than KwikWeld.

Main Differences in Details

J-B Weld KwikWeld is a fast-setting version of the Original Cold-Weld system. It provides solid and long-lasting repairs to metals and several other surfaces.

J-B Weld Original Cold-Weld is a two-part, steel-reinforced epoxy system that delivers long-lasting repairs to multiple surfaces.

Get detailed information about these two products to make a better comparison.

Tensile Strength

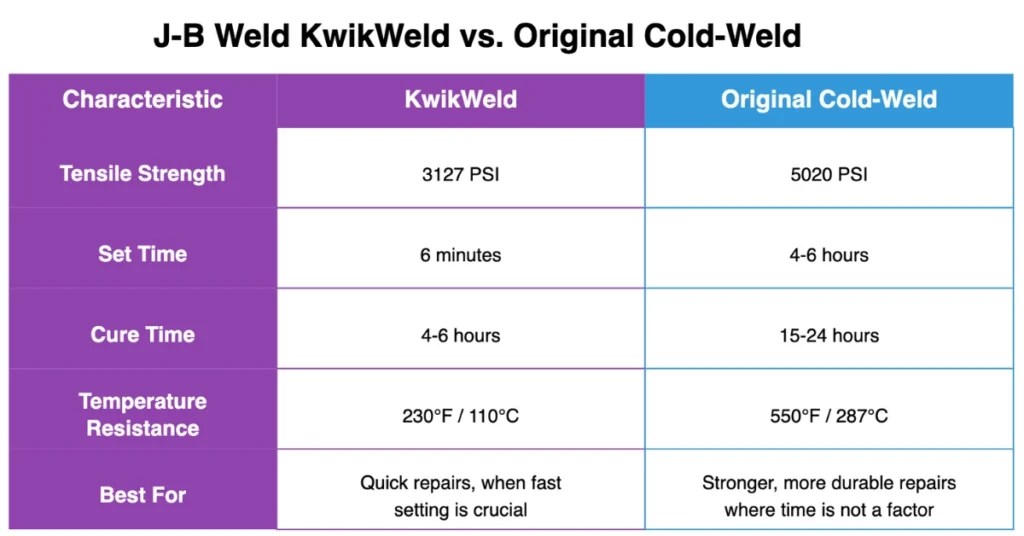

The KwikWeld has a tensile strength of 3127 PSI, which means that one square inch of KwikWeld has enough strength to hold 3127 lbs.

On the other hand, J-B Weld Original Cold-Weld has a tensile strength of 5020 PSI, which means that one square inch of Cold-Weld is strong enough to hold 5020 lbs.

The Original Cold-Weld is much stronger than the KwikWeld.

Set & Cure Time

The KwikWeld claims to take only 6 minutes to set and 4-6 hours to cure adequately. Once cured, it can be shaped, tapped, sanded, filed, and even drilled.

On the other hand, the Original Cold-Weld needs 4-6 hours to set and 15-24 hours to cure. After it has cured, it can be shaped, tapped, drilled, and painted.

So, clearly, the KwikWeld is super faster than the Cold-Weld. When the Cold-Weld sets, the KwikWeld can properly cure within that time.

Cure Color

Once cured, both the KwikWeld and Cold-Weld turn dark grey. Thus, their cure colors are similar.

Performance

Well, KwikWeld is an easy-to-use product. It is a fast-setting steel-reinforced one that provides a long-lasting outcome.

It is versatile and can be used on multiple surfaces.

Cold-Weld is a heavy-duty epoxy that delivers superior performance and quality, suitable for any DIY task.

Compatible Materials

The KwikWeld epoxy is multipurpose and can be used on surfaces such as steel, aluminum, wood, ceramic, fiberglass, brick, metals, concrete, and more.

When it’s about the Original Cold-Weld, it is compatible with materials like metals, rigid plastics, PVC, wood, ceramic, tile, stone, concrete, fiberglass, and more.

Applications

The KwikWeld epoxy is suitable to use on household repairs, automotive, plumbing, crafts, marine, DIY repairs, agricultural equipment, outdoor equipment, boats, motorcycle, personal watercraft, and more.

Another one is the Cold-Weld, which can be used for household repairs, automotive, marine, plumbing, crafts, DIY repairs, outdoor equipment, agricultural equipment, boats, toys, motorcycles, personal watercraft repairs, and much more.

Their purposes for repairs are the same. You can use either of the products you choose.

Temperature

KwikWeld can withstand the temperature of 230°F/110°C.

The cold weld can withstand the temperature of 550°F/287°C. So, it seems the Cold-Weld can tolerate more.

Method of Using

Both of the products come in a two-part formula. You need to dispense equal parts from both tubes.

Mix them well, then apply them to the area that needs repair to get a permanent bond.

Resistance

Once KwikWeld is fully cured, it becomes waterproof, petroleum, acid, and chemical resistant.

Talking about Cold-Weld, it is also waterproof and acid, chemical, and petroleum resistant once fully cured.

Editor’s Note

Strength, temperature capacity, and cure time are the significant differences between J-B Weld KwikWeld and Original Cold-Weld.

We have concluded that Cold-Weld is a good option based on all these factors.

It is much stronger than KwikWeld, has better temperature tolerance, and is easy to use on multiple surfaces.

You can only choose the KwikWeld if you want a quick repair, as it sets super fast. Otherwise, the Original Cold-Weld is a good option, too.