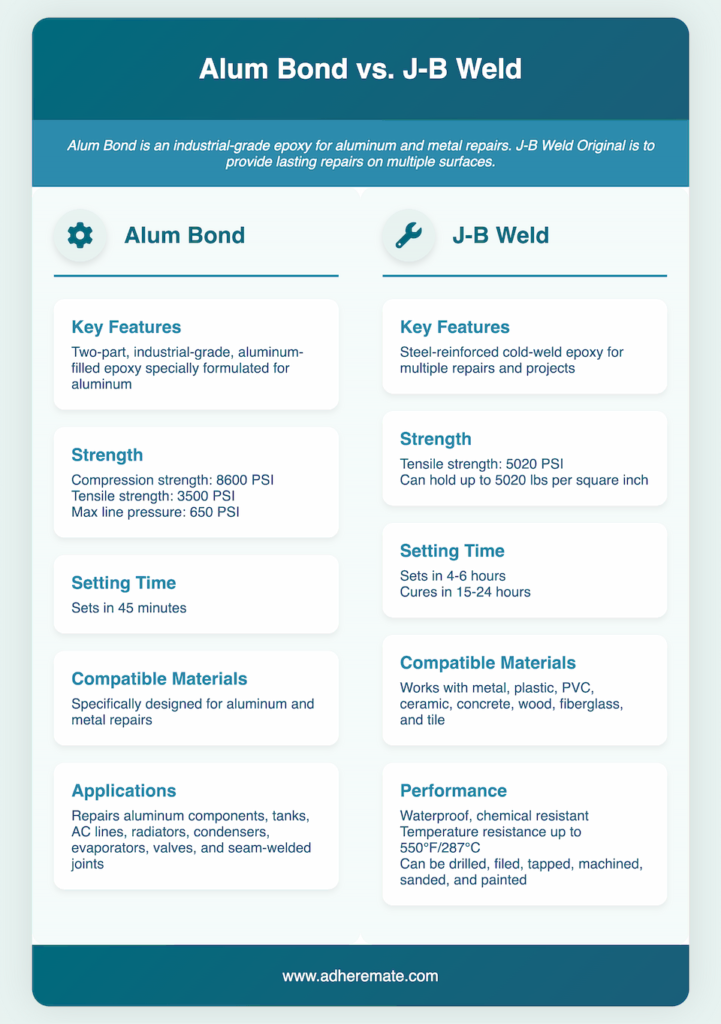

Alum Bond is a specially formulated, industrial-grade epoxy for aluminum and metal. It is aluminum-filled epoxy that provides good strength for repairs.

J-B Weld Original is a steel-reinforced, cold-weld epoxy for multiple repairs and projects. It is suitable for DIY, home repairs, automotive repairs, marine, crafts, and more.

However, both epoxies are different. You should first know about both products to identify the differences and compare them.

Article Highlights

- Alum Bond is a metal-filled polymer compound and non-rusting adhesive.

- J-B Weld Original is designed as an alternative to torch welding.

- Alum Bond is suitable for aluminum and metal repairs.

- J-B Weld Original is ideal for metal, plastic, fiberglass, tile, ceramic, and many more materials, making it versatile enough.

Alum Bond vs. JB Weld

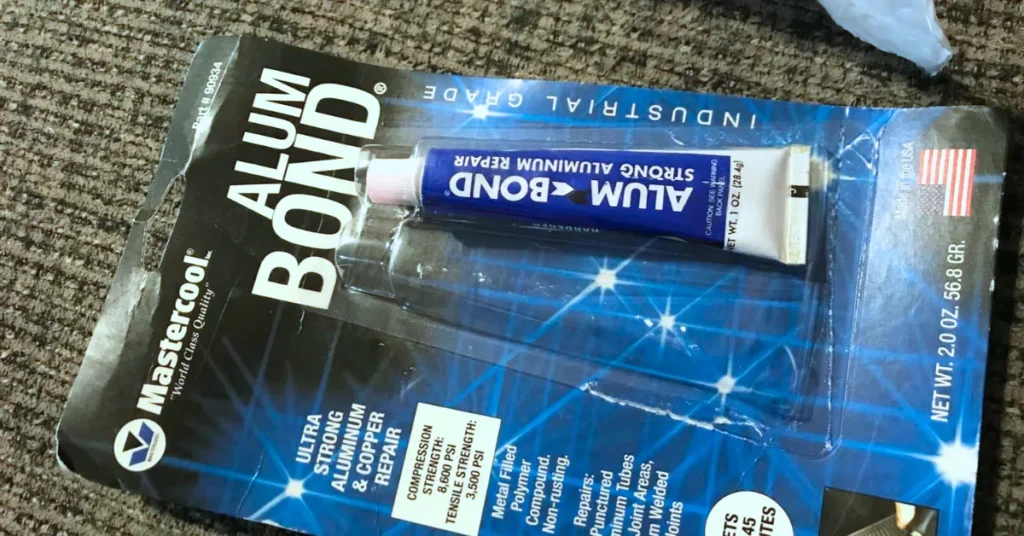

Alum Bond is a two-part, industrial-grade, aluminum-filled epoxy.

It is specially formulated to repair aluminum components, tanks, AC lines, radiators, condensers, evaporators, valves, and any aluminum repairs.

J-B Weld Original is an original cold-weld, steel-reinforced epoxy that provides lasting repairs. It’s excellent for all metals, fiberglass, stones, and more.

Whether it’s a big or small project, J-B Weld Original can do everything from heavy-duty to DIY work.

Strength

Alum Bond repair epoxy is an ultra-strong copper and aluminum repair material.

It has a compression strength of 8600 PSI and a tensile strength of 3500 PSI. Its max line pressure is 650 PSI.

J-B Weld Original has a tensile strength of 5020 PSI, which means that one square inch of the product can hold 5020 lbs.

For other metal-to-metal applications, the Belzona and J-B Weld comparison can offer insight into high-performance adhesives with industrial durability.

Setting Time

Alum Bond is a fast-drying formulated adhesive. It sets in 45 minutes.

J-B Weld Original sets in 4-6 hours and takes 15-24 hours to cure.

It dries dark gray and can be drilled, filed, tapped, machined, sanded, and painted.

Compatible Materials

Alum Bond is a product for aluminum and metal repairs.

J-B Weld Original can work on several materials, including metal, plastic, PVC, ceramic, concrete, wood, fiberglass, and tile.

For similar applications, you might also want to see JB Weld vs. Araldite, as Araldite offers a comparable range of uses in many household repairs.

Applications

Alum Bond repairs all aluminum components, including punctured aluminum tubes, seam-welded joints, and more.

It can also repair aluminum components, such as radiators, condensers, AC lines, evaporators, tanks, valves, or any aluminum component.

J-B Weld Original works on multiple surfaces and is easy to use.

It works on household repairs, automotive, plumbing, marine, crafts, DIY auto repairs, outdoor equipment, agricultural equipment, motorcycles, toys, personal watercraft, boats, and more.

Method of Using

Alum Bond comes in two products: resin and hardener.

You need to mix equal parts of both and then apply them to the areas that you want to repair.

J-B Weld Original is also the same. It comes with two-part products that need to be mixed at a 1:1 ratio to achieve the perfect, permanent repair.

Performance

Alum Bond has good bonding strength, doesn’t leak, and is easy to apply every time. It works and sticks well.

J-B Weld Original is a strong and non-toxic adhesive. It can withstand 550°F/287°C and has a temperature resistance of up to 550°F.

Moreover, it is steel-reinforced and considered an alternative to torch welding, providing a strong and long-lasting bond on multiple materials.

This Original J-B Weld is waterproof, chemical, petroleum, and acid resistant, delivering superior performance and quality.

Editor’s Opinion

Based on all the facts, I believe J-B Weld Original is more versatile and robust than Alum Bond.

It has a better tensile strength as proof and can provide permanent bonds like steel.

Alum Bond is a suitable adhesive for only aluminum and metal repairs.

However, J-B Weld Original can work with various materials, which is recommended.