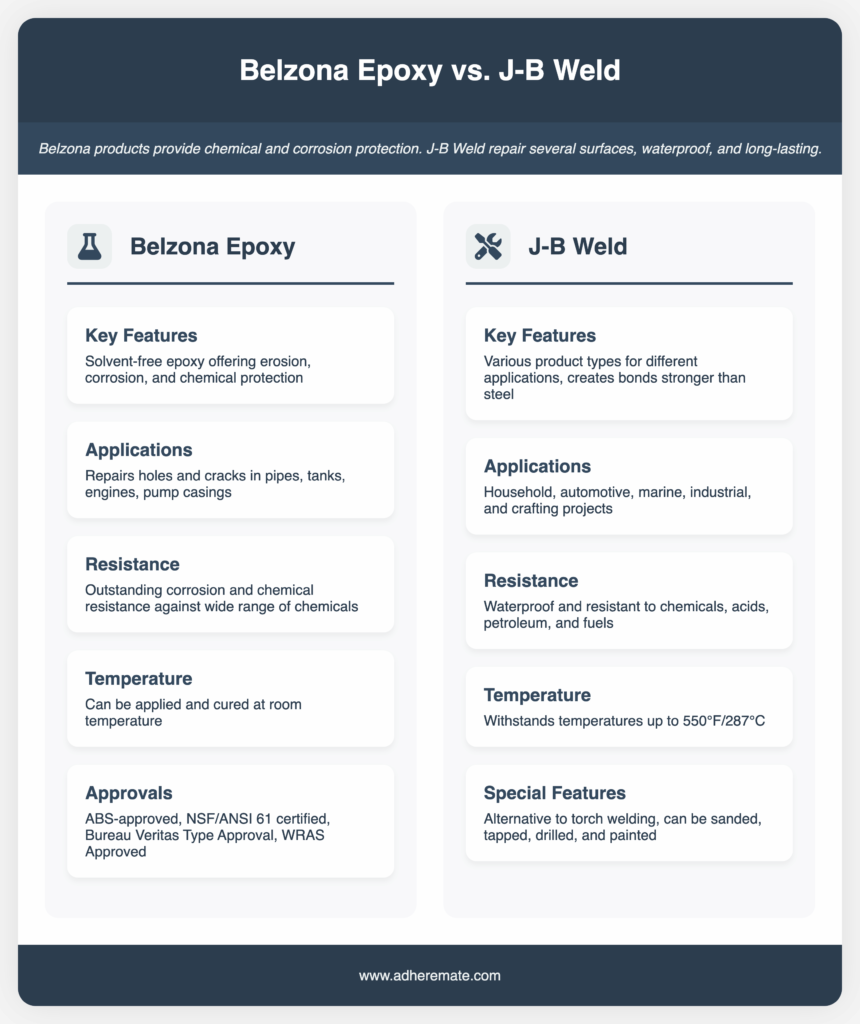

Belzona epoxies are solvent-free and offer erosion, corrosion, and chemical protection.

They’re great for repairing holes and cracks in pipes, tanks, engines, pump casings, and more.

J-B Weld products come in different varieties. They can be used on household, automotive, marine, industrial, and crafting projects.

Article Highlights

- Belzona 1111 is an epoxy-based composite for metal repairs.

- J-B Weld Original is considered an alternative to torch welding and creates a bond stronger than steel.

- Belzona 1111 is a high-strength structural adhesive that is great for metal bonding.

- J-B Weld products suit automotive, household, industrial, and more. Belzona is suitable for pipes, pump casings, engines, tanks, and more.

Belzona Epoxy vs. J-B Weld

Belzona epoxies are good-quality ones for several applications.

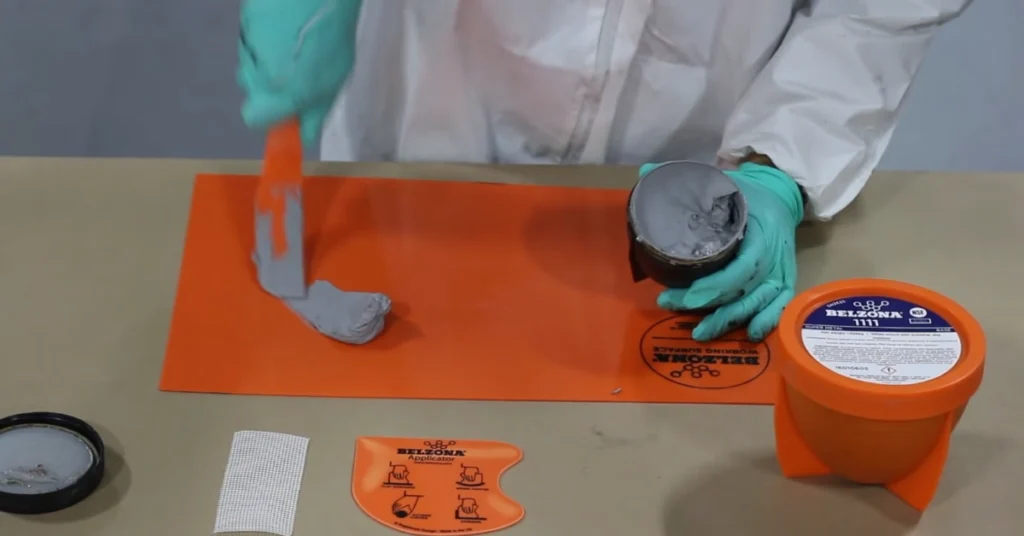

Belzona 1111 is a two-part composite for metal repairs and resurfacing based on solvent-free epoxy resin reinforced with silicon steel alloy.

Another Belzona product is Belzona 1212, a two-part surface-tolerant epoxy specially produced for applications on oil, wet, and underwater surfaces.

On the other hand, J-B Weld products come in different variations. J-B Weld Original is a two-part cold weld adhesive that provides robust and long-lasting repair to multiple surfaces.

J-B Weld KwikWeld is the fast version of the original cold weld. J-B Weld Plastic Bonder is a structural syringe adhesive for heavy-duty use.

Performance

Belzona 1111 is a multi-purpose, durable repair adhesive. It is fully machinable and can be used for conventional tools.

Also, it has excellent electrical insulation characteristics. The repair material resists a wide range of chemicals and will not corrode.

Furthermore, it is easy to mix and requires no specialist tools. It can be machined using conventional tools.

Belzona 1212 is also a multi-purpose, durable adhesive that is surface-tolerant too.

It provides rapid cure and doesn’t need specialist tools. It can be used underwater, with oil and damp surfaces.

J-B Weld Original is a durable and versatile adhesive with several uses. It is easy to use, sets fast, and dries dark gray. It can also be sanded, tapped, drilled, and painted.

Compatible Materials

Belzona 1111 has excellent adhesion to metals, including carbon steel, stainless steel, brass, aluminum, and copper.

It also adheres to several natural and synthetic materials, such as wood and glass.

J-B Weld Original works on materials like metal, plastic, fiberglass, wood, tile, PVC, ceramic, and concrete.

Applications

Belzona 1111 can repair cracks and holes in pipes, engines, pump casings, tanks, and other equipment.

It also repairs damaged shafts and hydraulic rams, resurfaces pitted metal surfaces, performs in-situ flange repair, makes irregular load-bearing shims, and reforms bearing housings.

Belzona 1212 is excellent for plate bonding, corrosion pit filling, and localized repair of wet, oil, or sweating-contaminated pipes where grit blasting cannot be achieved.

Moreover, it fixes oil and fluid leaks in engines, storage tanks, gearboxes, transformers, long-term repairs of marine equipment, ship hulls, offshore structures, underwater repairs, and more by in-situ sealing.

J-B Weld Original works well for household repairs, automotive, marine, plumbing, crafts, agricultural equipment, motorcycles, toys, boats, and more.

Approvals

Belzona 1111 is ABS-approved and certified to NSF/ANSI 61, Drinking Water, System Components-Health Effects, Bureau Veritas Type Approval, WRAS Approved Material, DNV Approval, and China Classification Society.

Belzona 1212 includes WRAS-approved material, while J-B Weld doesn’t include any of the approvals mentioned.

Applicable Temperature

Belzona 1111 can be applied and cured at room temperature, and it doesn’t require hot work.

Belzona 1212 can rapidly cure at low temperatures, making it suitable for emergency in-situ repairs without hot work.

J-B Weld can work and repair at higher temperatures. It withstands 550°F/287°C.

Special Features

Belzona 1111 is solvent-free, reducing health and safety risks. It has a simple mixing ratio and causes no shrinkage, distortion, or expansion.

Belzona 1211 can be machined using conventional tools.

Its excellent mechanical properties ensure long-lasting and durable repairs, making it ideal for emergency repairs.

J-B Weld Original Cold-Weld is considered an alternative to torch welding.

It provides strong, non-toxic, and lasting repairs to multiple surfaces and a stronger bond than steel.

Resistance

Belzona 1111 has outstanding corrosion and chemical resistance against a wide range of chemicals.

Belzona 1212 is solvent-free and has excellent corrosion and chemical resistance, as well as reduced health and safety risks.

J-B Weld Original is waterproof and, once fully cured, resistant to chemicals, acids, petroleum, and fuels.

For underwater repairs, you can explore the differences in J-B WaterWeld vs. MarineWeld vs. Original Cold-Weld, which provides details about J-B Weld’s top water-resistant products.

Which Products From Belzona and J-B Weld Are Good?

Belzona 1111 (Super Metal) vs. J-B Weld Original Cold-Weld Epoxy

J-B Weld has waterproof, chemical, acid, fuel, and petroleum resistance.

But Belzona 1111 only has corrosion and chemical resistance. So, in terms of that, J-B Weld Original is the better one.

Belzona 1212 vs. J-B KwikWeld

Belzona 1212 and J-B KwikWeld are considered rapid-action adhesives.

However, Belzona 1212 takes around 90 minutes or 1.5 hours to cure, while KwikWeld takes 4-6 hours. So, Belzona 1212 is faster than KwikWeld.

Belzona 1511 (Super HT-Metal) vs. J-B Weld ExtremeHeat

Belzona 1511 is suitable for applications up to 150°C (302 °F).

High-temperature epoxy can repair heat exchangers, process vessels, distillation columns, pump casings, tanks, pipes, and more.

It is solvent-free and resistant to corrosion, erosion, and chemicals. It can also be overcoated with Belzona high-temperature coating.

J-B Weld ExtremeHeat can perform repairs in high-temperature environments (1000°F / 537°C).

It is excellent for repairing small gaps, holes, and cracks in exhaust manifolds, holes, seam connections, pipe connections, outdoor grills, mufflers, water heaters, and more.

Also, it is water-based, solvent-free, and non-flammable.

Belzona 1311 (Ceramic R-Metal) vs. J-B WaterWeld

For instance, when comparing JB WaterWeld vs. PlasticWeld, you will notice that WaterWeld is great for underwater repairs. It’s ideal for repairing plumbing projects, tubs, showers, fuel tanks, drains, spas, pools, and more.

Belzona 1311 is designed for metal repairs. It is solvent-free, erosion, corrosion, and chemical-resistant.

It cures at room temperature and can perform several tasks, such as reconstructing the geometry of centrifugal and positive displacement pumps. It also repairs tube sheets, gate valves, pipes, and elbows.

Belzona 1321 (Ceramic S-Metal) vs. J-B Weld HighHeat

Belzona 1321 has long-term erosion and corrosion protection and chemical resistance on metal surfaces.

It is solvent-free and can repair pipe elbows, gate valves, fans, kort nozzles, and more.

J-B Weld HighHeat is a hand-mixable epoxy putty stick for high-temperature and industrial maintenance applications.

It works on exhaust manifolds, tail pipes, engine blocks, mufflers, ductwork, machinery, and other high-temperature equipment.

Editor’s Note

Belzona and J-B Weld offer a wide range of products for different uses.

However, J-B Weld is more professional in its illustrations of its features and uses.

Belzona products are chemical, erosion, and corrosion-resistant, which is a plus.

J-B Weld products are more versatile. They include household, watercraft, industrial, and more products.

If you need a more solution, consider exploring J-B Weld vs. Araldite, which examines the performance of these two well-known brands for household and industrial repairs.