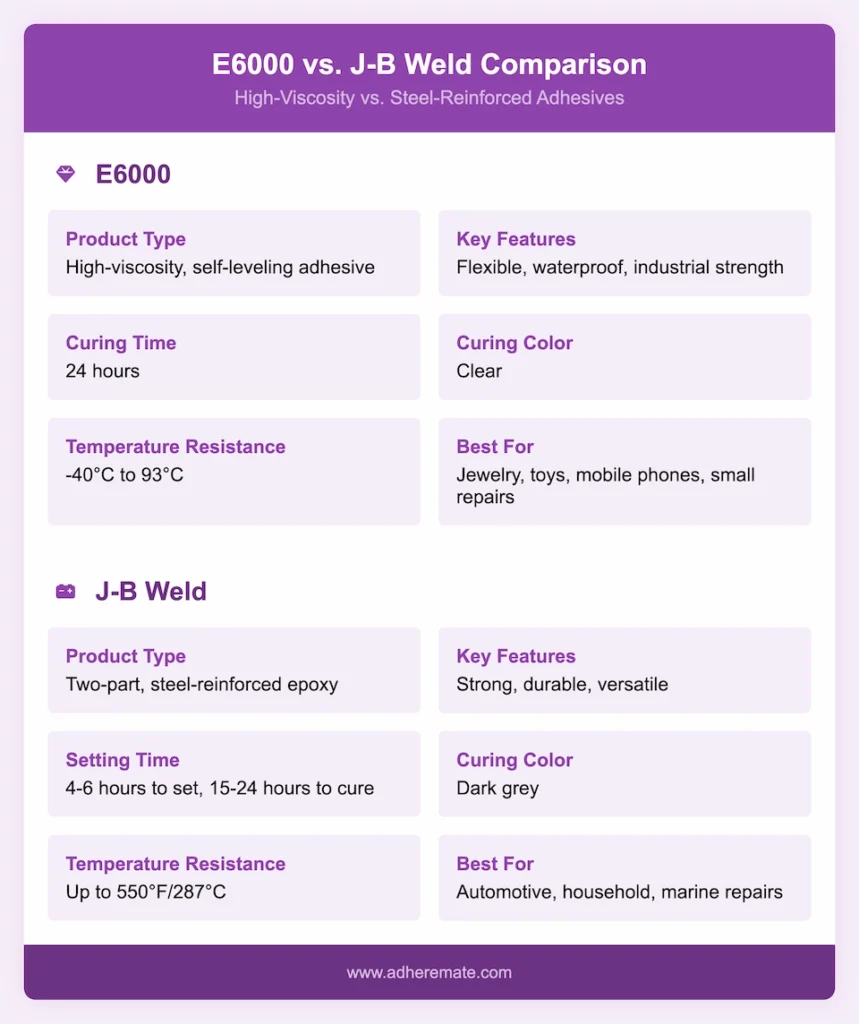

E6000 and J-B Weld are two famous brands that produce high-quality bonding.

Each adhesive has different characteristics, including different adhesion technology and durability.

E6000 glue comes with a high-viscosity feature. It works on multiple surfaces and can repair jewelry, toys, footwear, mobile phones, etc.

J-B Weld is a two-part, steel-reinforced glue suitable for household, automotive, marine, crafts, and other projects like these.

Article Highlights

- E6000 is a high-viscosity adhesive suitable for minor repairs like toys, jewelry, mobile phones, footwear, and more.

- J-B Weld is a steel-reinforced adhesive for automotive, household, plumbing, marine, toys, outdoor equipment, motorcycle repairs, and more.

- E6000 dries clear, but J-B Weld turns dark grey after curing.

- E6000 is ready to use, but J-B Weld comes in a two-part formula that needs to be mixed.

E6000 vs. JB Weld Original

E6000 is a multi-purpose adhesive tube. It can be applied to oil and water-based paints and has a unique multi-media art and crafts formula.

It also provides a strong, flexible, and waterproof bond on all porous and non-porous surfaces.

Conversely, J-B Weld Original Cold-Weld is a two-part adhesive system that provides solid and long-lasting repairs on multiple surfaces.

After curing, it should be mixed at a 1:1 ratio to form a permanent, high-strength bond.

Strength

E6000 adhesive is an industrial-strength self-leveling adhesive with high viscosity, durability, and a permanent bond that can withstand different conditions.

It is a versatile glue that is suitable for various surfaces and repairs.

Its tensile strength is 3200 PSI, which means that one square inch of the E6000 glue can hold 3200 lbs.

It also claims to be tougher, 2X stronger, and 60X more flexible than polyurethane. E6000 is non-flammable, resistant to extreme heat and cold, and temperature-resistant once cured.

J-B Weld has a tensile strength of 5020 PSI, which means that one square inch of the glue can hold 5020 lbs.

JB Weld is also versatile and compatible with outdoor tasks, with a higher temperature tolerance.

Read More: Devcon vs. J-B Weld

Setting And Curing Time

E6000 glue cures within 24 hours. It dries clear once cured.

J-B Weld glues take 4-6 hours to set and 15-24 hours to cure. It dries dark grey after curing.

Also, J-B Weld adhesives can be sanded, drilled, tapped, molded, shaped, and painted.

Compatible Materials

E6000 provides a strong and flexible bond on all types of porous and non-porous materials, such as wood, glass, metal, ceramic, fiberglass, rubber, plastic, masonry, concrete, and more.

Conversely, J-B Weld works on multiple surfaces, such as metal, wood, plastic, PVC, tile, concrete, ceramic, stone, fiberglass, and more.

Applications

E6000 can be used for many applications, such as repairing, attaching, and sealing.

It is used for jewelry making, decorating, repairing mobile phones, toy repairs, footwear repairs, and many other arts and crafts projects.

Besides, it is available in a tube with a thin nozzle and airtight cap for precise application.

E6000 is safe for applications exposed to dilute acids and dilute caustics.

It maintains a flexible bond in cold temperatures, which makes it even more versatile.

J-B Weld is used for household repairs, automotive, plumbing, marine projects, DIY, crafts, outdoor equipment, toys, motorcycles, boats, personal watercraft, agricultural equipment, and more.

It is easy to use. You only need to dispense equal amounts of both parts, mix, apply, and dry.

Temperature

The E6000 adhesive can withstand temperatures between -40º to 93 ºC.

It has a temperature resistance that helps to tolerate extreme heat or cold temperatures after curing.

J-B Weld can withstand 550°F/287°C. Once set, it delivers strong, non-toxic, and temperature-resistant bonds, as explained in comparisons like J-B Weld TankWeld vs. SteelStik.

Resistance

E6000 is an industrial-strength glue that is waterproof, chemical, UV, and temperature resistant.

It is safe for applications exposed to dilute acids and caustics. Once completely cured, it can be submerged in fresh and salt water.

Also, it is flexible and has a high viscosity that is enough to provide excellent bonds. Once cured, J-B Weld is waterproof and resistant to petroleum, acid, chemical, and fuel.

E6000’s UV and waterproof nature makes it a great choice for outdoor decorations or jewelry exposed to the elements.

J-B Weld’s resistance to chemicals and fuels makes it indispensable for automotive and plumbing repairs.

Caution

E6000 is harmful to vapor, and prolonged exposure can cause skin irritation, eye irritation, dizziness, and headache.

J-B Weld is a non-toxic adhesive, but skin contact with it can cause irritation.

Editor’s Note

J-B Weld provides a stronger bond than E6000. It can handle tougher tasks in automotive, marine, household, crafts, toys, and more.

E6000 is suitable for small repairs on jewelry, toys, decorations, mobile phones, footwear, and toys.

In my opinion, J-B Weld is the superior choice for large, heavy-duty projects requiring maximum strength. E6000, however, provides a flexible, evident bond for delicate, small-scale repairs, making it ideal for intricate or decorative projects.

If you’re dealing with intricate projects that require water resistance or exposure to extreme temperatures, the J-B WaterWeld vs. MarineWeld vs. Original Cold-Weld guide will help you choose the right adhesive for your needs.