Most epoxy putties can create a strong bond with metals. However, they will not last long on industrial and automotive parts exposed to high temperatures.

In most cases, it’s best to take it to a repair shop. But that can be expensive, like losing an arm or leg!

That’s where JB Weld High Heat Epoxy comes in! It’s three times stronger than standard epoxy putties in high-heat situations, similar to how SteelStik handles challenging repairs under extreme conditions.

This particular glue can handle scorching temperatures, like 450 degrees Fahrenheit all the time or 500 degrees Fahrenheit for a little while. It’s easy to use when it’s the right temperature. Let’s see how it works!

How To Use JB Weld High Heat Epoxy Putty?

JB Weld High Heat Epoxy Putty is perfect for tailpipes, mufflers, machinery, engine blocks, and exhaust manifolds. It sets in one hour and cures within 8 hours.

Nevertheless, some users report that leaving it untouched for 24 hours will cure the putty properly. That also depends on the temperature where you keep it. If it’s in a warmer place, it will set too quickly.

Gather Your Materials

- JB Weld High Heat Epoxy Putty

- Gloves

- Light sandpaper (100-200 grit)

- Clean cloth

- Acetone

- Clamps

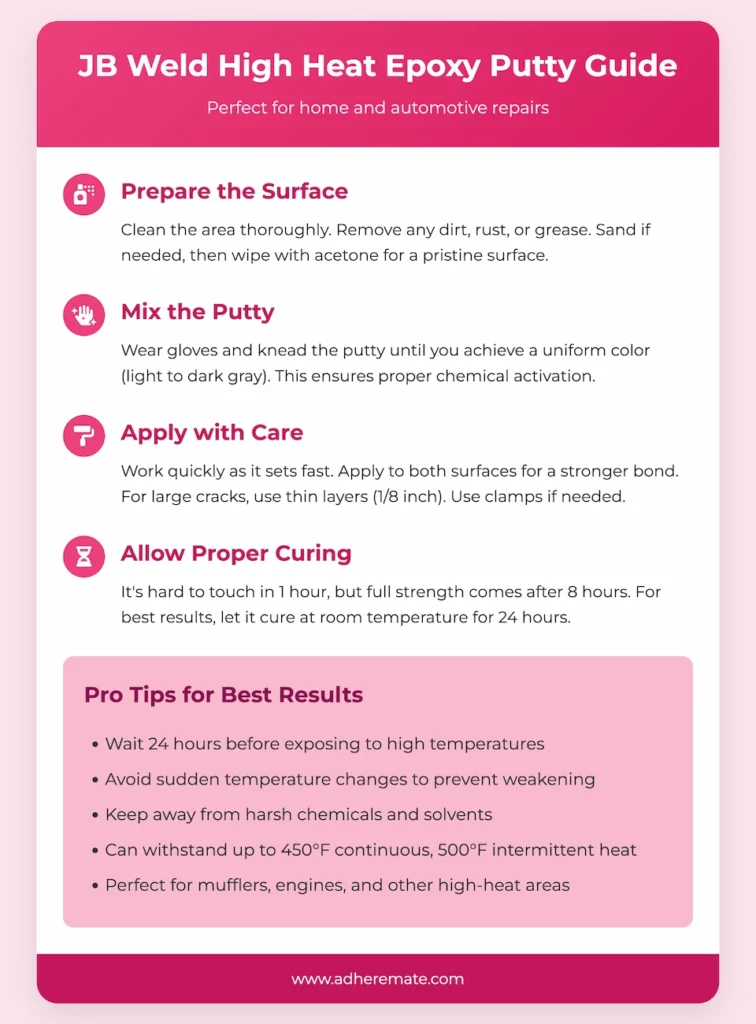

Clean The Area

Cleaning the broken area is always crucial, especially before applying high-heat epoxy putty. You want to ensure there’s no rust, dirt, or grease on the surface—just as you would when using Plastic Bonder for a durable bond.

Moreover, sand the area with light sandpaper if necessary. Then, apply acetone and remove any grease with a clean cloth. Your surface is now ready for high-heat epoxy putty.

Knead the Putty

Now that the surface is clean, the second step is to mix the putty. The JB Weld High Heat Epoxy Putty is hand-mixable. Meaning you don’t need any extra tools to mix the product.

Wear protective gloves and knead the putty with your finger until you see a uniform color. When it’s ready, the color should be light to dark gray.

Apply the Putty

Apply as quickly as possible since the putty will be set soon.

Make sure to apply epoxy to both surfaces for a stronger, more reliable bond. This step is critical whether you’re working with high-heat epoxy or using JB Weld Steel Reinforced Epoxy for metal surfaces.

If you’re bonding two parts, clamps can hold them in place while the epoxy cures. To avoid air bubbles, apply the epoxy in thin layers (1/8 inch or 3mm at a time) for large or deep cracks. Let each layer set slightly before applying the next.

Let it Cure

Almost done with that fix! The putty will be hard to touch in about an hour, but it needs more time to get super strong, like 8 whole hours.

Here’s a tip: keep it somewhere warm, like 70 degrees Fahrenheit (that’s about room temperature!), for 24 hours. This will help it cure perfectly.

After waiting a day, you can use a drill, sandpaper, file, or even a little hammer to work on your epoxy. Just remember, use them gently. Don’t push too hard, or you might crack your fix.

You can use a heat gun on a low setting or even a low-heat oven to speed up the curing process. But be careful! Too much heat (like over 150 degrees Fahrenheit) can mess up your fix.

Post Care for JB Weld High Heat Epoxy

1. Allow Full Curing Time

Let the epoxy fully cure for 24 hours at room temperature before exposing it to high heat. Gradual exposure to increasing temperatures is important, just like when using JB Weld Exhaust System Sealant for automotive fixes.

After the initial curing period, expose the epoxy to gradual heat. Start with lower temperatures and slowly increase to the maximum temperature the epoxy can handle (up to 450°F or 232°C), ensuring it sets properly.

2. Avoid Extreme Temperature Shocks

Gradual Heating: Avoid sudden exposure to extremely high heat immediately after the curing process. Rapid temperature changes can weaken the bond or cause cracks.

Even Heating: Ensure the heat is distributed evenly across the repaired area to prevent uneven expansion or stress.

4. Avoid Harsh Chemicals

Keep the epoxy away from solid solvents, oils, and chemicals that could weaken the bond, especially in high-temperature environments.

For safety guidelines on using epoxy products, check out OSHA’s safety resources on chemical exposures.

5. Monitor for Stress Points

Once cured, avoid applying mechanical stress or force on the bonded area for the first few uses to allow the epoxy to adjust fully.

Editors Opinion

I’ve used JB Weld High Heat Epoxy, which is a reliable fix for high-temperature repairs. Its heat resistance of up to 500°F makes it perfect for car parts and exhaust systems.

It’s easy to apply and shape, hardens in an hour, and fully cures in about 8 hours. Sanding can be tricky, as too much pressure might cause cracks. Overall, it’s a solid, durable option when used correctly.