If you are unsure which epoxy to choose for your application or repair, I hope this article helps you clarify the issue.

Well, J-B Weld produces permanent, long-lasting, and high-quality performance. This brand’s WaterWeld is for outdoor applications and can cure underwater, too.

MarineWeld is known for its strong repairs and works well for marine, automotive, and household needs.

Its reliability in tough conditions is similar to the performance you’d find in TankWeld, which is another great option for heavy-duty tasks.

Cold-Weld is quite similar to MarineWeld, offering robust and lasting results across various materials. If you’re weighing your options, checking out the differences between Cold Weld and MarineWeld can be quite enlightening.

Article Highlights

- WaterWeld is a waterproof two-part epoxy that can be used indoors and outdoors.

- MarineWeld is a hand-mixable epoxy that is used primarily for marine repairs.

- The Original Cold-Weld from J-B Weld can provide long-lasting outcomes.

- The WaterWeld is the quicker one among these three products to set and cure.

Detailed Comparison

The J-B Weld products are not only renowned but also high-quality products.

The J-B Weld WaterWeld is a specially formulated two-part epoxy putty that is hand-mixable and can cure under water.

J-B Weld MarineWeld is a two-part cold-weld adhesive system that delivers strong and lasting repairs on different or similar materials, such as metals, fiberglass, aluminum, and more.

The other product is the J-B Weld Original Cold Weld two-part epoxy system, which provides long-lasting repairs on metal and similar surfaces. J-B Weld claims this product is an alternative to torch welding.

Tensile Strength

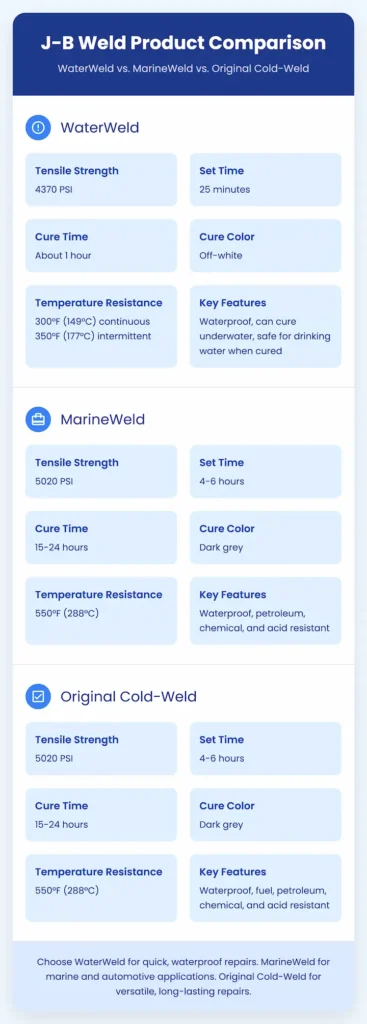

WaterWeld’s tensile strength is 4370 PSI, which means one square inch of the product has enough tensile strength to hold 4370 lbs.

It also claims to hold ten times more home water pressure than regular products.

Another product is MarineWeld from J-B Weld. It has a tensile strength of 5020 PSI, which means that one square inch can hold 5020 lbs.

The other product is the Original Cold-Weld from J-B Weld, which has the same tensile strength as MarineWeld, 5020 PSI.

In this case, MarineWeld and Cold-Weld have similar and better tensile strength than WaterWeld.

Set And Cure Time

The WaterWeld sets in about 25 minutes and cures in about an hour. After curing properly, it can be sanded, drilled, tapped, filed, and painted.

On the other hand, MarineWeld needs 4-6 hours to set and 15-24 hours to cure. It’s durable enough to be sanded, tapped, painted, and drilled.

The Cold-Weld needs the same time as the MarineWeld. It requires 4-6 hours to set and 15-24 hours to cure adequately.

It can also be sanded, filed, tapped, drilled, and even shaped. Cold-weld is also non-toxic.

So, overall, the WaterWeld is the fastest one.

Cure Color

Once cured, WaterWeld has an off-white finish, blending well with various surfaces. If color matching is important, you might also consider the clear options available with ClearWeld, which offers different aesthetic choices.

Compatible Materials

The WaterWeld is highly versatile. It bonds on many surfaces, including all metals, iron, aluminum, fiberglass, rigid plastics, PVC, brass, copper, stone, concrete, and more. It works both indoors and outdoors.

On the other hand, J-B Weld MarineWeld works on metal, fiberglass, aluminum, alloy steel, plastic, PVC, wood, composite, concrete, ceramic, tile, and more.

The last one is the Original Cold-Weld, which works on multiple surfaces, such as metal, wood, plastic, PVC, fiberglass, tile, ceramic, concrete, and more.

Applications

WaterWeld is a good product for repairing showers, tubs, plumbing, drains, fuel tanks, marine, boats, potable water tanks, glass repair, flooring, spa, pools, wall repairs, underwater repairs, masonry, tabletop coating, countertop repairs, and a lot more.

When it’s a MarineWeld, it can also be used for household, automotive, and marine repairs.

You can also use it for watercraft, in/outboard engines, deck and hull accessories, marine and water repairs, boats, plumbing, outdoor equipment, agricultural equipment, and more.

Lastly, the Original Cold-Weld works on household, automotive, marine, plumbing, crafts projects, outdoor, agricultural equipment, watercraft, boats, toys, motorcycles, in/outboard engines, deck & hull accessories, and more.

Using Method

The using process of the J-B Weld WaterWeld is simple.

You need to remove a needable amount of product, knead it, mix it well, and then apply it to the areas to repair cracks and holes.

WaterWeld is easy to use. It molds to fix anything and shapes everywhere. It is hand-mixable, which makes it convenient for DIY repairs.

The directions of MarineWeld are also simple. First, clean off the dust, grease, paint, oil, rust, or anything else from the surface, then roughen with sandpaper.

Equal parts of the product from both tubes should be mixed well. Then, apply it with an appropriate tool for an even coating and leave it to cure properly.

The Cold-Weld is an easy-to-use product. To use it, dispense from both products at a 1:1 ratio and mix it well. Apply on the areas and let it sit to set properly until it turns dark grey.

Temperature

The WaterWeld can withstand continuous temperatures of 300oF/149oC and intermittent temperatures of 350°F/177°C.

MarineWeld can withstand 550°F/288°C. And the Original Cold-Weld can withstand 550°F/288°C.

So, both the MarineWeld and Cold-Weld can tolerate more temperature than WaterWeld.

Resistance

The WaterWeld is resistant to water, gas, oil, hydraulic fluids, diesel, petroleum, acid, and most chemicals. Once fully cured, it is safe for drinking water.

The MarineWeld is waterproof, petroleum, chemical, and acid resistant.

Conversely, Cold-Weld is also waterproof and resistant to fuel, petroleum, chemicals, and acids.

Editor’s Opinion

As you can see, these three products have some similar features. However, their application processes are different.

WaterWeld is the fastest-curing epoxy, good for both outdoor and indoor repairs. MarineWeld is for marine and watercraft repairs.

Cold-Weld is for automotive, marine, and watercraft and is very similar to MarineWeld.

Hi would WaterWeld be suitable to repair a split 25mm x 4mm in a PVC shower floor membrane the split is in the floor to wall bend ?

Yes, JB WaterWeld would be a good option for repairing that split in the PVC shower floor membrane. It provides a strong, waterproof bond and sets even underwater, which makes it great for wet environments like a shower. Just be sure to clean the area well before applying, especially around the bend. If the area moves a lot, you could also consider a silicone-based sealant for a bit more flexibility. Good luck with your repair!