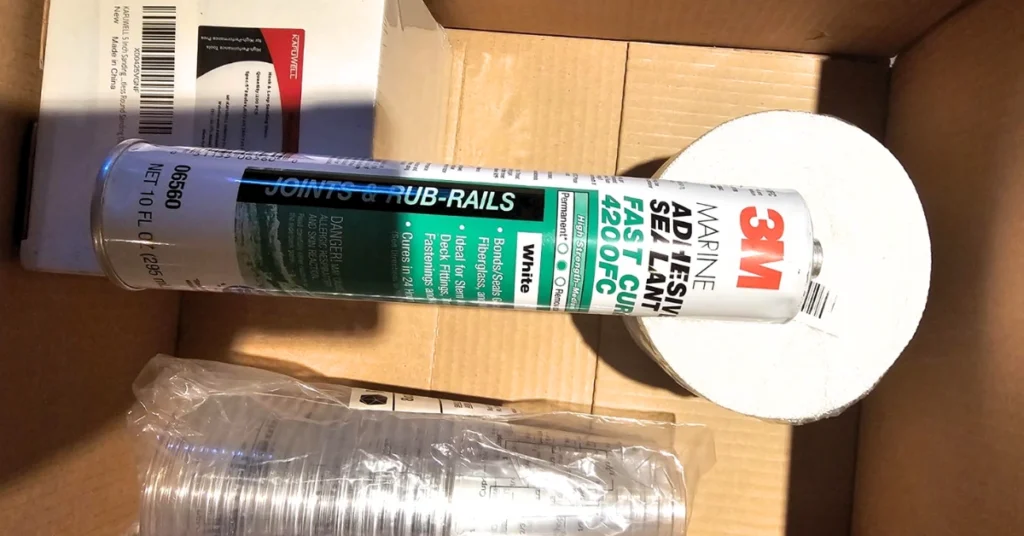

I love to DIY fix everything, including my water vehicles. Several months ago, I needed to fix my motorboat. But I needed clarification about whether to go for 3M 4000 or 3M 4200 since both are great. Eventually, I did the job and learned much about 3M 4000 vs. 3M 4200.

While 3M 4000 and 4200 are removable marine sealants, 3M 4000 is comparatively stronger. It also offers UV resistance and can be used on various surfaces, unlike 3M 4200. Both adhesives cure pretty fast, are suitable for water vehicles, paintable and sandable.

You are still weighing your options. If you need more detailed information about them, I urge you to proceed.

3M 4000 vs. 4200

As you can see from the table I shared above, the 3M 4000 and 4200 adhesives are similar in some ways. Yet, they have certain differences. Now, let’s explore their similarities and differences in more detail.

Adhesive Type

Both 3M 4000 and 4200 are semi-permanent adhesives. It means even if you use them to seal various areas, you can disassemble them if needed. But are they easy to remove? Yes, they are.

Formula

The 3M 4000 has an SMP or silane-modified polymer formula, while the 4200 has polyurethane. If you don’t know, polymer is more flexible and suitable as a sealant than polyurethane.

Industries They Are Used In

As I mentioned initially, I used the glues on my motorboat. However, they can also be used on other types of objects and materials. However, using the 3M 4200 is more limited than 4000.

For example, the 4000 adhesive is more versatile. It is suitable for fiberglass, aluminum, wood, plastic, or anything from the industrial, marine, or general industry. On the other hand, the 3M 4200 is more suitable for the marine industry.

Water Vehicle Use

I have checked various forums and spoken to professionals before applying them on my boat. According to most of them, the 3M 4200 is more suitable for underwater use, while the 4000 is more suitable above water level.

UV Resistance

One of the best parts of the 3M 4000 adhesive is that it is UV-resistant. You can apply it to objects exposed to sunlight without worrying about color damage or any other effects.

However, the 4000 adhesive does not stay white forever. Many users have experienced that it gets yellowish with age. On the other hand, the 3M 4200 doesn’t offer such protection and keeps getting yellowish faster due to exposure.

Paintability

Go right ahead if you want to sand or paint over the glue. Because both 3M 4000 and 4200 can be sanded and painted over without major issues. However, I suggest waiting for the glue to cure completely.

Strength

When it comes to strength, the 3M 4000 easily beats the 4200. With a 500 psi tensile strength, it offers a stronger bond, while the 3M 4200 has a tensile strength of 300 psi.

Cure And Tack Free Time

Both 3M 4000 and 4200 have a fast cure time, typically 24 hours. However, the 4000 glue will begin to skin within 30 minutes of application. On the other hand, the 4200 glue can take up to 90 minutes.

Read More: JB Weld Marine vs. Original

Pros And Cons of 3M 4000

Pros

- Suitable for a range of surfaces

- It can be used on plastic

- UV resistance

- Cures faster

- Forms skin faster than 4200

- Can be painted immediately after application

Cons

- Not very suitable for using underwater

- Some users experienced leaking

- It turns yellowish over time

Pros And Cons of 3M 4200

Pros

- More suitable for underwater parts

- Corrosion-resistant

- Very flexible

- Can withstand rough weather conditions

- Easy to remove

Cons

- Not UV resistant

- The surface often gets yellowish on exposure

- It takes longer to form skin

Editor’s Opinion

Comparing 3M 4000 vs. 4200 has given me many ideas about their future usage. I hope it helped you, too. They are both excellent bonding agents and can work on many things. The best part is that you can remove them if needed.

But which one is the right one? Well, there isn’t a definite answer. It all depends on what you expect from it. Yet, if you are still unsure, this article is here for the rescue.